Yes, this image is not spaghetti, it's fettuccini. Let's not get lost in this particular detail. I wanted to write about a very simple tool you can use tomorrow to find wasted motion in your workplace. And I mean any workplace. I think, actually, office type work may be one of the larger culprits here. Much of the activity is walking about already, lost opportunity for reduced motion is not as considered. Sure, you have some zealous managers insisting people are always at their desk. We're not getting into leadership today, maybe next time.

No, I want to talk spaghetti string maps.

The what?

A spaghetti string map is a very simple improvement tool anyone can employ to observe the flow of people and stuff in a space. We call it this as it is a map with lines, and they are very much like spaghetti on the paper. It may actually be a fun exercise to make one and use real spaghetti. I haven't tried this, maybe you should and tell me about it.

visualizing routes

=

saving time

If you cannot understand flow in your space, you won't find the wasted time. There is always wasted time, find it.

Although this is a simple action, it can pay-off rapidly.

Starting somewhere with your spaghetti strings

- Draw a simple map of the space you want to understand.

- Based on the process, pick a starting point.

- Draw a line through the map for the path taken first.

- Draw another for the next paths taken.

- Draw the travel for all the paths until said process is done.

Sometimes, it isn't one process. It is the general routing of the day. Occasionally it is one route, and it is repeated over and over. Sometimes a simple route has some exception you should account for too.

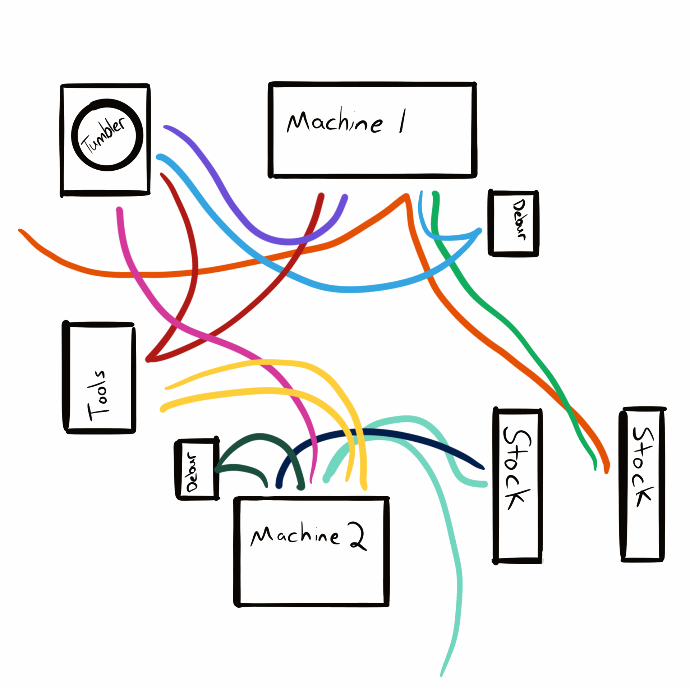

For illustration, I made two very simple spaghetti strings to look at.

The first map shows lots of paths into and out of the simple work cell. I grew up in machine shops, so if this is one of those, assume each path happens multiple times a day.sometimes it is useful travel, other times not.

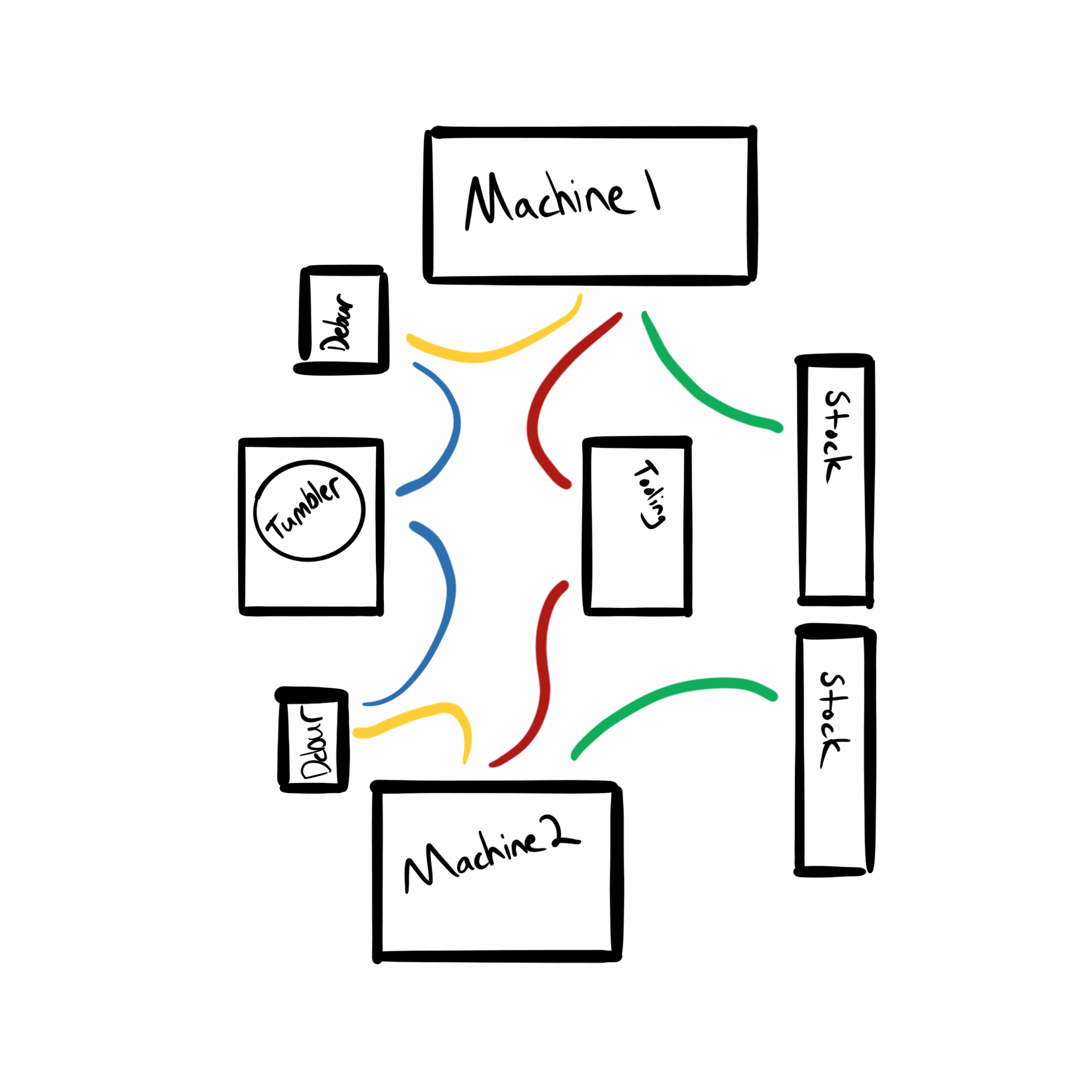

Now look at the second map.

We moved some of the associated equipment while keeping the machines in place. The paths are shorter now. In some cases you can remove a path altogether by considering what the work cell needs. Even with this simple example, a single shift operation, removing 3 minutes a day of wasteful motion is redirecting perhaps $1,000 (~250 working days, loaded hourly at ~$75) a year at value added activity. Now consider if you have five work cells with 10 operators. More?

Using spaghetti strings shouldn't happen all by itself. Leverage other tools along with this to maximize your value added time.Though I haven't really hammered on 5S implementations, this is an occasion where they can contribute to your time waste removal. If we assume this work cell rearrangement includes 5S of the workstations and general area, the potential improvement of value added time could exceed expectations.

Leading people to seeing the waste

If you think this tools is right for you, do a mini workshop with the people in the work cell. They will understand all the paths and the stupid each one may include. Leverage their understanding of their work to find an optimal flow. You can introduce them to a useful tool, give them ownership, and provide the satisfaction of making their own situation better. Also, be willing to test it out. I like to give any idea (possible ideas) two weeks to play with how it works.

Now, you'll notice I didn't move the machines in my example. In a previous post I talked about a lean improvement technique called OSKx3. As such, layout is one of the last things it recommends changing because moving equipment is hard, expensive, and if you're wrong, it can be a big problem. Move the simple stuff first if you're gonna move anything. Sometimes, the machine moves result in technical issues you didn't foresee vs. moving work benches or storage cabinets. While you're mapping, I'd map the layout change before I did it anyway. Then you can look at a few arrangements before you commit at all.

Spaghetti string the office too

You would be surprised how useful this tool is for office settings as well. Trips to the copier. Trips to get ink. Routing paperwork. Finding people for signatures. Office workers should give this a try as well. Especially if you have the opportunity to plan a floor layout ahead of time and can make your approval paths flow nicely.

If you'd like to work on your facility flow, I can help. My programs are designed to teach you and your employees the basics of process improvement. In about 30 days you'll be finding your own problems, getting to root causes, and cutting out the waste. Whether you start with spaghetti strings or process maps, I'll get you on the path to improved quality from the inside out.

So drop me a line and together, we can start somewhere.