This is related to my success story about material storage. I felt like a visualization of how flow chart use resulted in the solution. So this one is brief and I thought you might be interested in the drawing of the rack, so it is linked below.

Rehash the Problem

Space, there is only so much of it in your building and the regular ways to store metal just aren't cutting it. You looked at Uline, Global Industrial, and half a dozen other storage gear sellers. Nobody has what can help you. So you decide to figure it out and see what happens.

You make a flowchart of the material receipt, handling, and use process:

Receive

Store

Process

Use

Your problem is mainly with space for the long bar and tube stock. So you look at your flow chart.....and you think......what if I cut the material after receipt? Then the flow looks like this:

Receive

Process

Store

Use

Now you have small bar, mostly ~4' or shorter. What can you do with that? Oh yeah, you have two 16' pallet racks. If there was a crate/rack to accommodate the cut material, you could store it in the racks you own. The thing has to allow you to grab it and move it around with a forklift too...

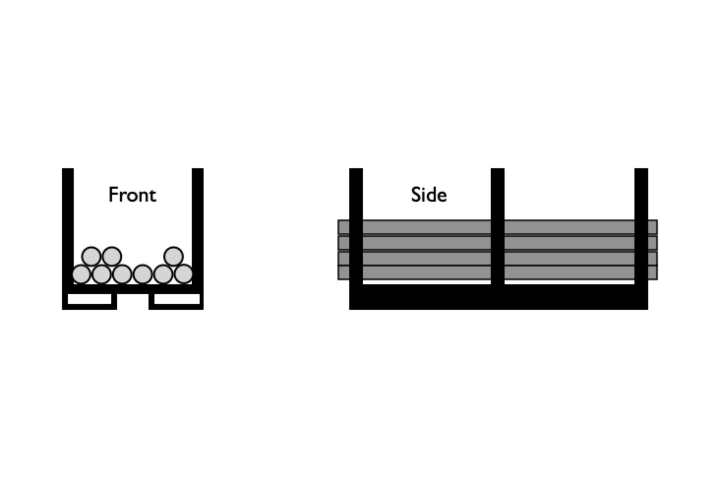

The stock holding rack:

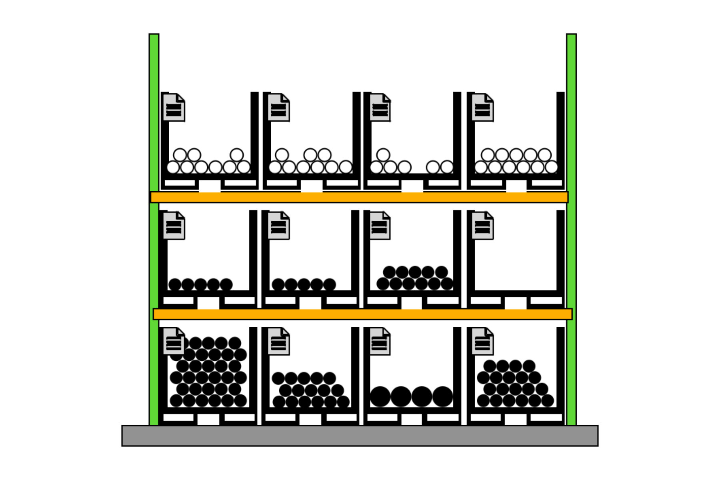

The system all put together in a pallet rack:

Now, you get your stuff, you cut it to size (you know the size, you ordered it for a job), and store it with the lot and job label. Ben better- you don't have to have people move it on carts from the stock room any more. You have your lift pull it out and if you elect to make them with side cutouts, use a pallet jack to shuttle them to their machine. you can even put a pallet rack or two on the floor as a pick location.

Start. Somewhere. & Visual Tools

This solution came about by using flow charts and within the visualization tool allowing the team to think about what they needed rather than what solutions existed. There was some cost in time and materials to make the containers, the removal of many other related bottlenecks was such a net positive the ~$10k for racks (we made 30-40, I forget exactly how many) had no operational impact.

The valuable lesson here was in leveraging the process "why" and not allow existing paradigms to control where the solution went. To this day, NOBODY makes this rack. I'm working on changing this, but still, when you search "metal storage racking" you get the same-old, same-old.

If you're interested at all in this idea, the "technical" drawing is linked below. No logins, data inputs, just a link. If you can use this system good on you.

If you'd like to see where I or myself systems can help you, schedule a call below.